Background

Crates protect objects during transport from shock and vibration, punctures, dents and abrasion, impact and distortion, and environmental hazards such as temperature and humidity extremes, water, pollutants and pests. 1,2 Crate construction tends to follow a standard design depending on the distance traveled, type of handling, and most importantly the fragility of the housed objects. A shell exterior protects objects from impact, strain and compressive forces. Crate shells are typically made from wood for limited use or composite fiberglass for multiple uses. Additions to this shell exterior increase function, such as the rain cap and handles. Interior padding made from petrochemical-based foams serve to absorb and reduce vibration and impact. Soft wrapping material of tissue or synthetic films protect the object surface from contact with the other packing materials in the crate. All the materials serve to buffer temperature and humidity fluctuations.

The high standards concerning the function and performance of crates cannot be compromised. To meet these standards, conservators and art packers depend on cushioning potential calculations that determine the vibration related to each crate component. Based on these calculations, cultural heritage professionals have identified standard packing materials, such as sheet foams, that offer consistent shock absorption with established performance ratings.3

Within these performance requirements, crates are designed and built for single use, round trip use, or increasingly long term reuse. Crate materials and their use patterns negatively impact the environment, but limited documented research exists connecting reuse with meaningful environmental benefits.4 In this LCA case study, four types of crates and three major material categories (exterior, interior, and wrapping) were analyzed, giving each configuration an environmental profile. The study compares crate options over their life cycles, including environmental impacts resulting from material production, crate assembly, transportation, and eventual disposal. These comparative results provide information on environmental impact to support decision making around crate design and use that complement the current trove of information on cost and performance of crate components.

1 Canadian Conservation Institute. 2020. “The CCI Chanel Crate: Making a Lightweight, Reusable Crating System – Canadian Conservation Institute (CCI) Notes 20/1.” https://www.canada.ca/en/conservation-institute/services/conservation-preservation-publications/canadian-conservation-institute-notes/lightweight-reusable-crate.html

2 Canadian Conservation Institute. 2021. “Five Steps to Safe Shipment – Canadian Conservation Institute (CCI) Notes 20/3.” https://www.canada.ca/en/conservation-institute/services/conservation-preservation-publications/canadian-conservation-institute-notes/five-steps-safe-shipment.html.

3 Barber, Chris. 2015. “Dynamic Cushion Curve Prediction – An Improved Formula for Practical Use in Preventative Conservation.” Preparation, Art Handling, Collections Care Information Network (PACCIN). https://www.paccin.org/content.php?293-Dynamic-Cushion-Curve-Prediction.

4 Clarke, Roddy. 2019. “UK Startup Launches New Art Packaging Solution Set To Revolutionize The Industry.” Forbes, September 28, 2019. https://www.forbes.com/sites/roddyclarke/2019/09/28/uk-start-up-launches-new-art-packaging-solution-set-to-revolutionise-the-industry/?sh=10e4e5ae6283.

LCA Modeling

Life cycle assessment (LCA) is an internationally standardized (ISO 14040) modeling tool used to quantify environmental and health impacts of a product or process.5 LCA takes a holistic, systems approach by considering sustainability over the entire product life cycle, including raw materials extraction, manufacturing, transport, and end-of-life.6,7,8 LCA has been implemented across all types of sectors to inform procurement decisions, and provides the scientific basis for all carbon, water, and environmental footprinting. For example, popular online calculators use LCA to compare different grades of paper and packaging materials.9,10

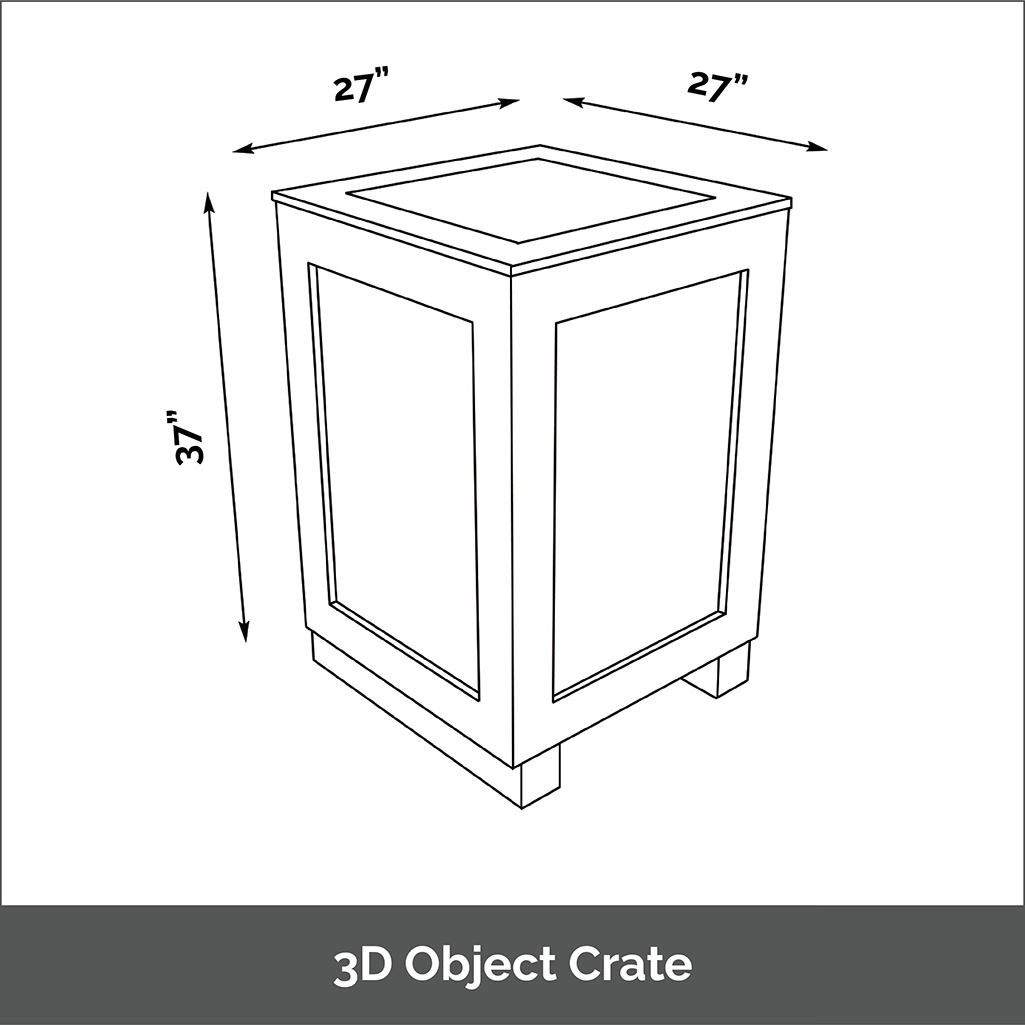

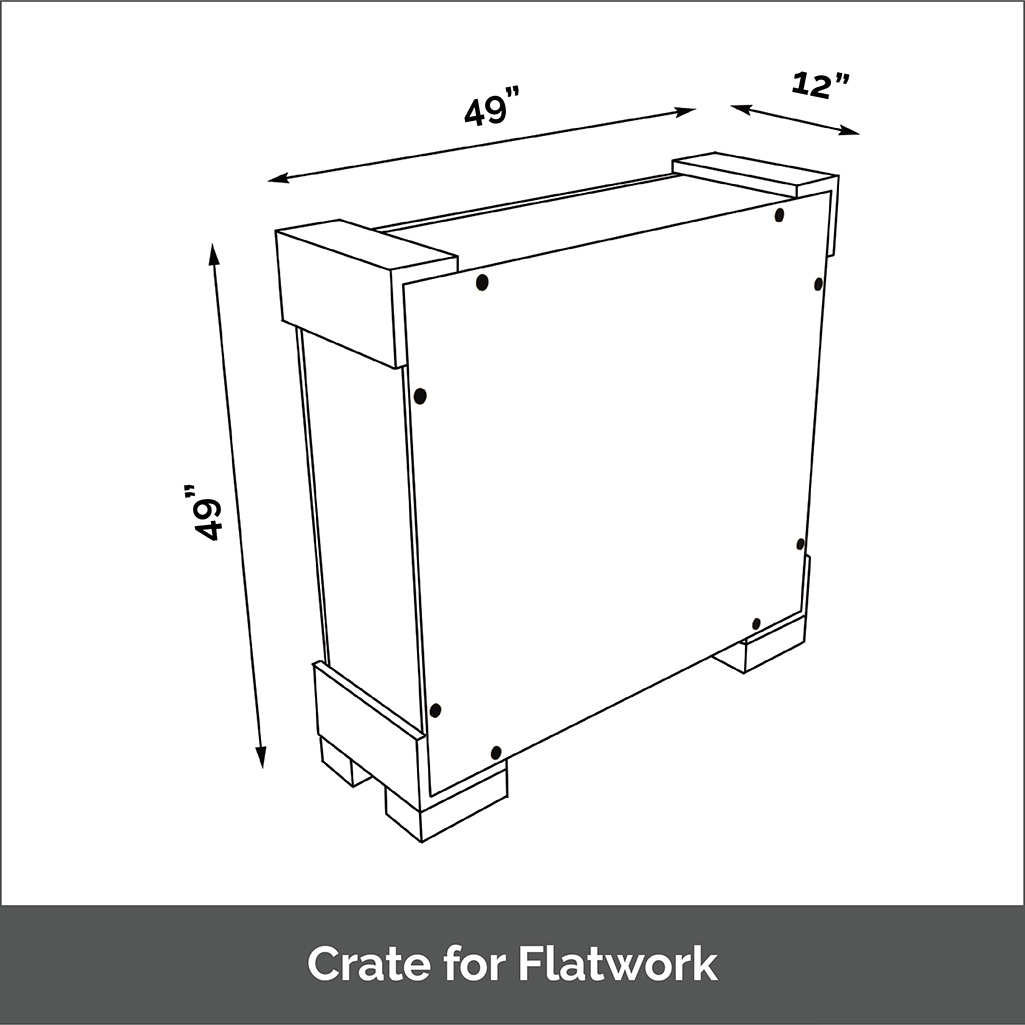

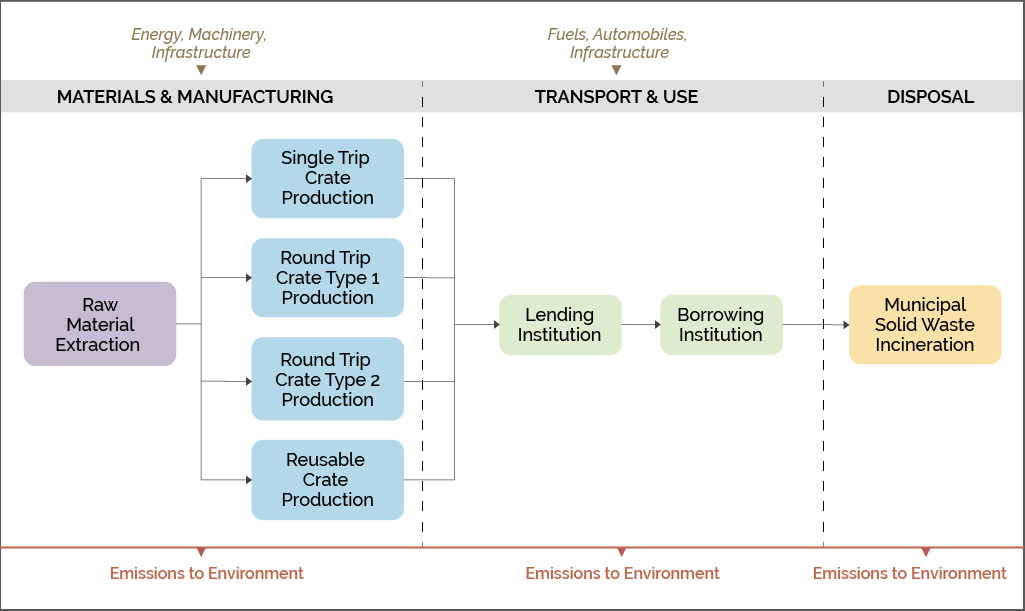

This case study covers a ‘cradle-to-grave’ scope, examining all stages of the product life cycle (Figure 1). LCA compares options based on the function that they provide, called a “functional unit,” allowing for fair comparisons. This case study considers two different functional units, corresponding to two types of objects (Illustrations 1 and 2).

LCA modeling was completed using the free, open source software OpenLCA (v1.10.3)11 with material-specific data from the ecoinvent database (v3.7, APOS).12 Global warming (carbon footprint, measured in carbon dioxide equivalents) and 9 other categories of environmental and human health impacts from each product life cycle were calculated using the Tool for the Reduction and Assessment of Chemical and other environmental Impacts (TRACI v2.1) impact assessment method developed by the U.S. Environmental Protection Agency.13 Further information concerning tools and methods can be found in the Introduction to LCA Information Sheet (STiCH website).

5 International Organization for Standardization (Switzerland) Environmental Management. 2006. “Life cycle assessment – Requirements and guidelines.” https://www.iso.org/standard/38498.html.

6 Vignon, Bruce W., D. Tolle, B. Cornaby, H. Latham, C. Harrison, T. Boguski, R. G. Hunt, and J. Sellers. 2020. Life-cycle assessment: Inventory guidelines and principles. N.p.: CRC Press.

7 Fava, James A., and Society of Environmental Toxicology and Chemistry. 1991. A technical framework for life-cycle assessment: workshop report; August 18-23, 1990. N.p.: SETAC.

8 UNEP. 2005. Life Cycle Approaches: the Road from Analysis to Practice. N.p.: UNEP/SETAC, Life Cycle Initiative, Paris.

9 Environmental Paper Network. 2021. “Paper Calculator: presented by environmental paper network.” https://c.environmentalpaper.org/.

10 sphera. 2020. “GaBi Packaging Calculator – Sustainable Packaging Design.” https://gabi.sphera.com/international/software/gabi-envision/gabi-packaging-calculator/.

11 GreenDelta. 2020. “openLCA.” https://www.openlca.org/.

12 ecoinvent. 2020. “Systems Models in ecoinvent 3: Allocation at the Point of Substitution.” https://www.ecoinvent.org/database/system-models-in-ecoinvent-3/apos-system-model/allocation-at-the-point-of-substitution.html.

13 U.S Environmental Protection Agency. 2012. “Tool for Reduction and Assessment of Chemicals and Other Environmental Impacts (TRACI).” https://www.epa.gov/chemical-research/tool-reduction-and-assessment-chemicals-and-other-environmental-impacts-traci.

Methods

MODELING PROCESS

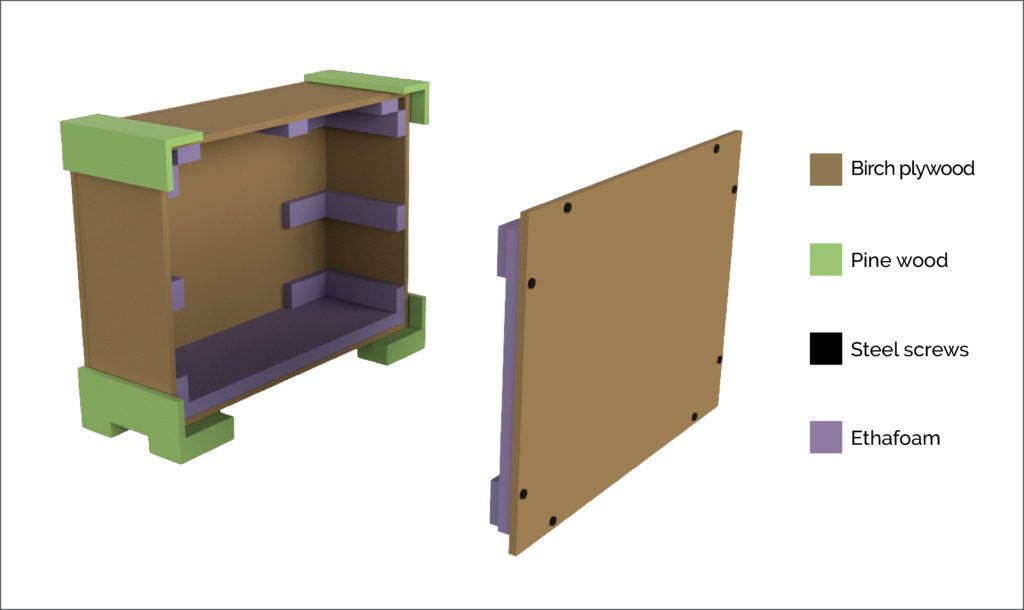

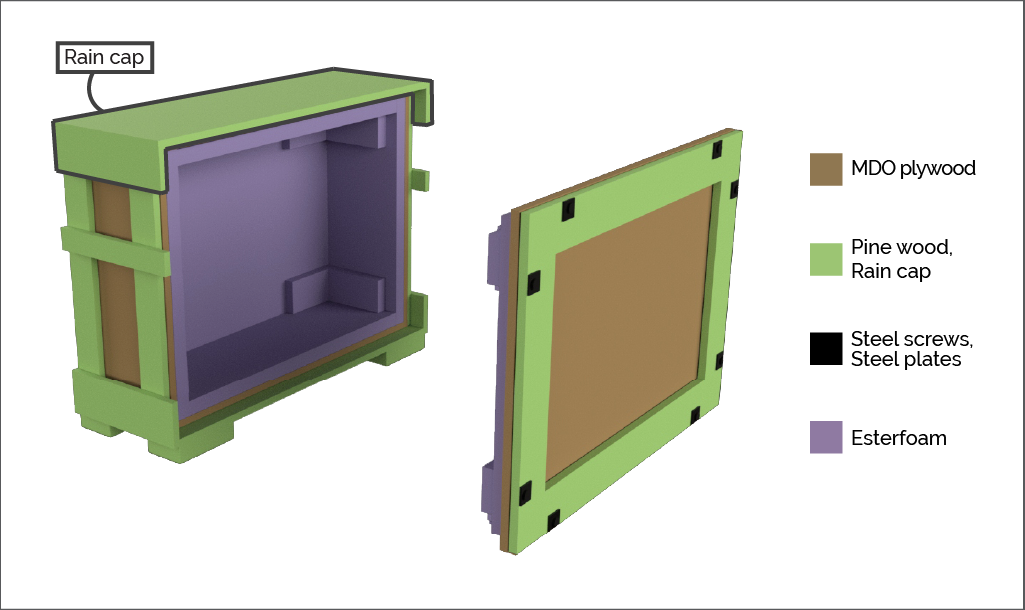

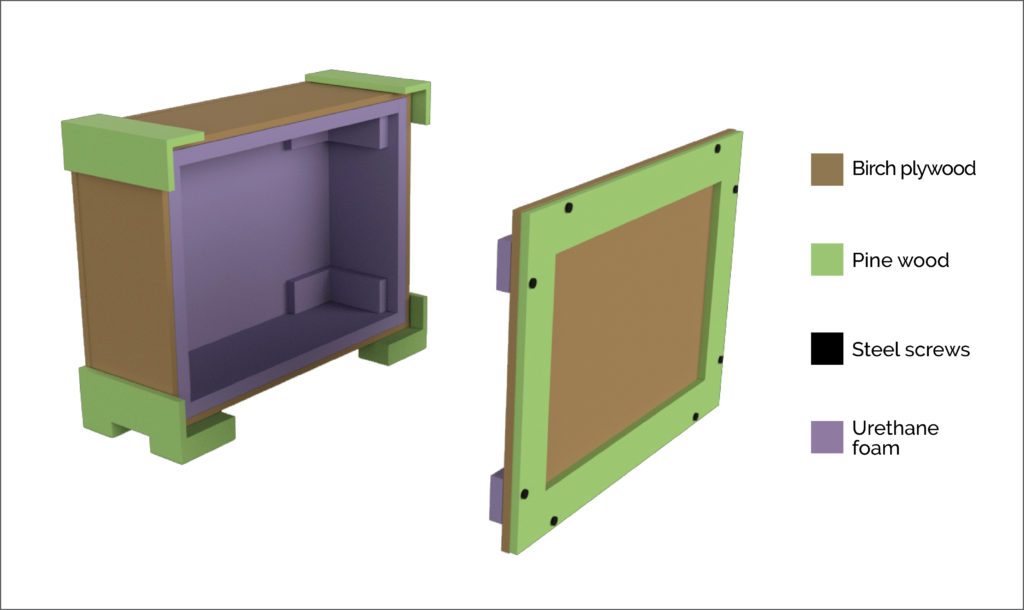

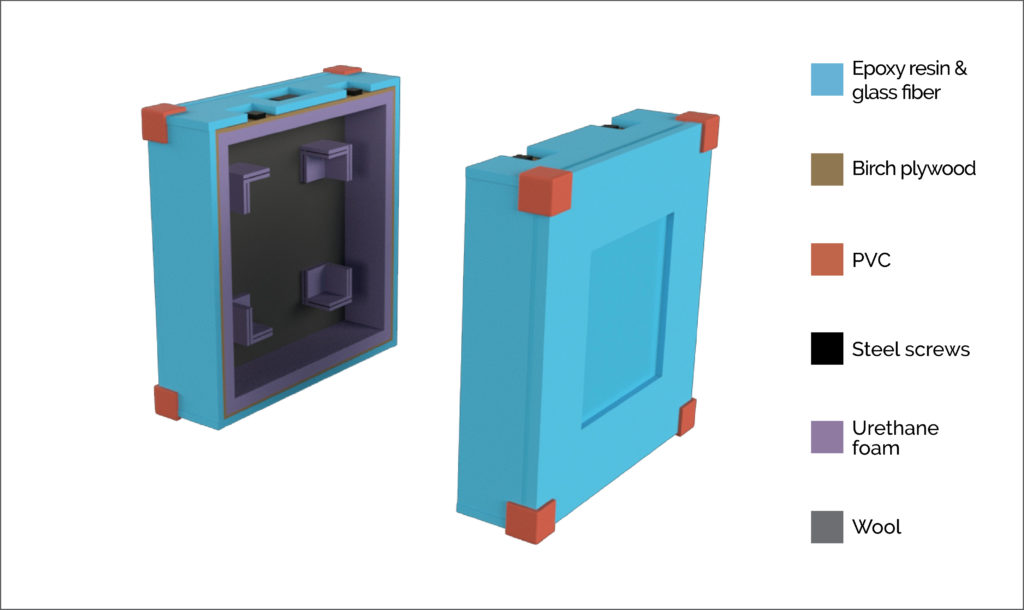

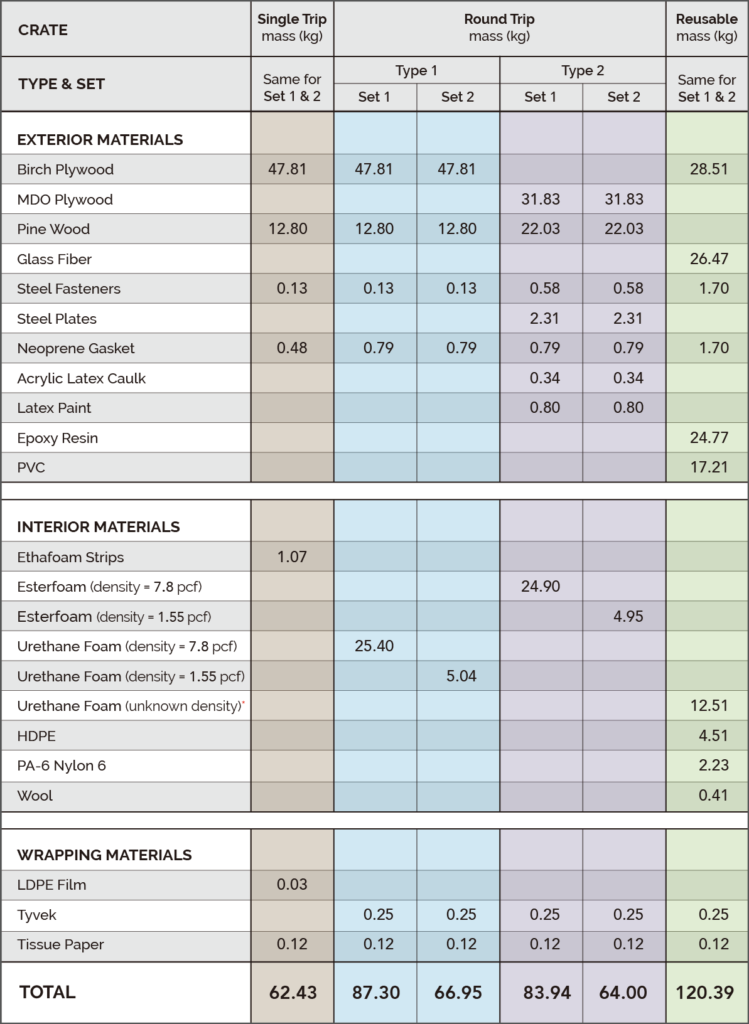

Four crate types were modeled, including single trip, round trip (two designs, termed here ‘type 1’ and ‘type 2’), and reusable. Two sizes were considered for each crate, for a total of seven crate scenarios (the reusable crate was not available for the 3D size). Single use and round trip options were wooden crates with various levels of hard shell protection and vibration absorption. These were compared with each other and with a hard shell reusable crate. Each crate was modeled to house one object or one painting wrapped first with tissue paper and then spunbound high density polyethylene sheet (Tyvek) or low density polyethylene film (LDPE). Crate composition, weight, and other specifications were collected from conversations with crate makers, art packers, and conservators. The crate assemblies are shown in Illustrations 3-6 below, detailing the shell, interior padding, and fasteners. Although the impacts of Tyvek, LDPE, tissue paper, gasket, and paints were analyzed, they are not included in these illustrations for simplicity.

The single trip crate assembly is composed of birch plywood, pine wood, steel fasteners, neoprene gasket, two inch open cell polyethylene foam (Ethafoam), LDPE, and tissue paper. It has the least amount of foam of the four crates. The round trip type 1 crate assembly is composed of birch plywood, pine wood, steel fasteners, two inch polyurethane ether foam (urethane foam), Tyvek, and tissue paper. The round trip type 2 crate assembly is composed of medium density overlay plywood (MDO), pine wood, steel fasteners and plates, neoprene gaskets, acrylic latex caulk, latex paint, two inch polyurethane ester foam (esterfoam), Tyvek, and tissue paper. Both type 1 and 2 have similar volumes of foam but type 2 requires more pine wood to construct the rain cap. The reusable crate assembly is composed of birch plywood, glass fiber, steel fasteners, neoprene gasket, epoxy resin, rigid polyvinyl chloride (PVC), urethane foam, high density poly ethylene film (HDPE), nylon, wool, Tyvek, and tissue paper. This crate includes components not found in the other three crate assemblies, most importantly, the fiberglass shell.

Not shown: neoprene gasket, LDPE film, and tissue paper.

Not shown: neoprene gaskets, acrylic latex caulk, latex paint, Tyvek and tissue paper.

Not shown: Tyvek, and tissue paper.

Not shown: HDPE, nylon, neoprene gasket, Tyvek and tissue paper.

Table 1 details the design and material differences among the crates. Set 1 and 2 have the same crate designs and solely differ in foam densities for the round trip type 1 and 2 crates, with values listed below.

*The density for the urethane foam used in the reusable crate was proprietary information, making it inaccessible for this study.

TRANSPORTATION/USE

This case study examined crates designed specifically for the protection of objects and paintings during transportation between two cultural heritage institutions, and not for other uses such as short or long term storage. Transportation by truck was modeled from New York, New York to Miami, Florida, a distance of 2,060 kilometers. This corresponds to the lifetime of 1 single trip crate, ½ of a round trip crate, and 1/200 of a reusable crate. The object/painting was assumed to weigh 6.8 kilograms (15 pounds), while the weights of the crates varied between 50 and 130 kilograms.

DISPOSAL

At the end-of-life stage, all crate materials were assumed to be incinerated as standard municipal solid waste. For bio-based materials, such as wood, incineration releases the carbon that was sequestered during plant growth.

STUDY SCOPE

This study excluded the inputs and materials needed to produce the paintings or objects, as these are identical for each crate. Additionally, the study excluded packaging and transportation of the crate materials, crate assembly, and transportation of the fully assembled crate to the first cultural heritage institution, as any differences among options are expected to be minor.

Earlier LCA studies addressed courier-related impacts, and demonstrated that courier travel can account for the majority of a museum loan carbon footprint.14 Reactions to virtual and bookend couriers vary, with updated positions stated in the AIC Position Paper on Virtual Courier Oversight.15 Recent guidance16 and track-and-monitor opportunities17 allow for safe, cautious transport of collections while implementing new climate-smart practices. In order to focus on comparing crate designs, this case study excluded the courier.

14 Nunberg, Sarah, Matthew J. Eckelman, and Pamela Hatchfield. 2016. “Life Cycle Assessments of Loans and Exhibitions: Three Case Studies at the Museum Fine Arts, Boston.” Journal of the American Institute for Conservation 55 (1): 2-11. https://doi.org/10.1080/01971360.2015.1112465.

15 American Institute for Conservation. 2021. “AIC Position Statement on Virtual Courier Oversight.” American Institute for Conservation. https://www.culturalheritage.org/docs/default-source/administration/governance/aic-positionstatement-virtual-courier-oversight.pdf?sfvrsn=b1761420_4.

16 UK Registrars Group. 2020. Guidance notes: The Virtual Courier (UK and Europe). https://www.ukregistrarsgroup.org/wp-content/uploads/2020/06/UKRG-Virtual-Courier-Guidance.pdf.

17 articheck. n.d. “Introducing…Virtual Courier: The world’s first software system designed to reduce risk before, during, and after shipment.” https://www.articheck.com/virtual-courier/.

Results

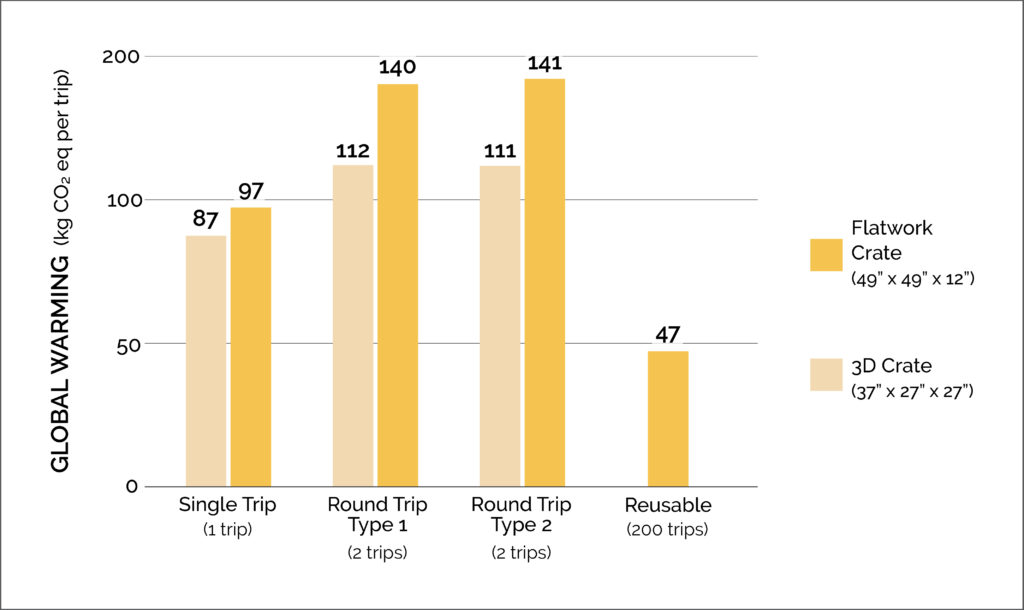

The results show that the round trip crates have the highest total global warming impacts (carbon footprints) for each size. Despite the differences in materials and their quantities between the type 1 and 2 crates (Table 1) the resulting global warming impacts are similar, with the type 1 crates having 112 and 140 kg CO2 eq compared to the type 2 crates at 111 and 141 kg CO2 eq. Perhaps surprisingly, the single trip crates have the lowest carbon footprint among the wooden crate options, demonstrating trade-offs in the embodied carbon associated with the additional materials in the round trip crates.

The fiberglass reusable crate has the lowest impact per trip of the four crate types studied, with a 52% lower impact than the single trip flat crate and a 67% lower impact than the round trip type 2 flatwork crate. As a break-even analysis, if the lifetime of the wooden crates could be extended past their original designs, the single trip crate would have to be used for at least four trips while the round trip type 1 and type 2 crates would have to be used for at least 16 and 15 trips respectively, in order for the per trip global warming impact to be less than that of the reusable crate (47 kg CO2 eq).

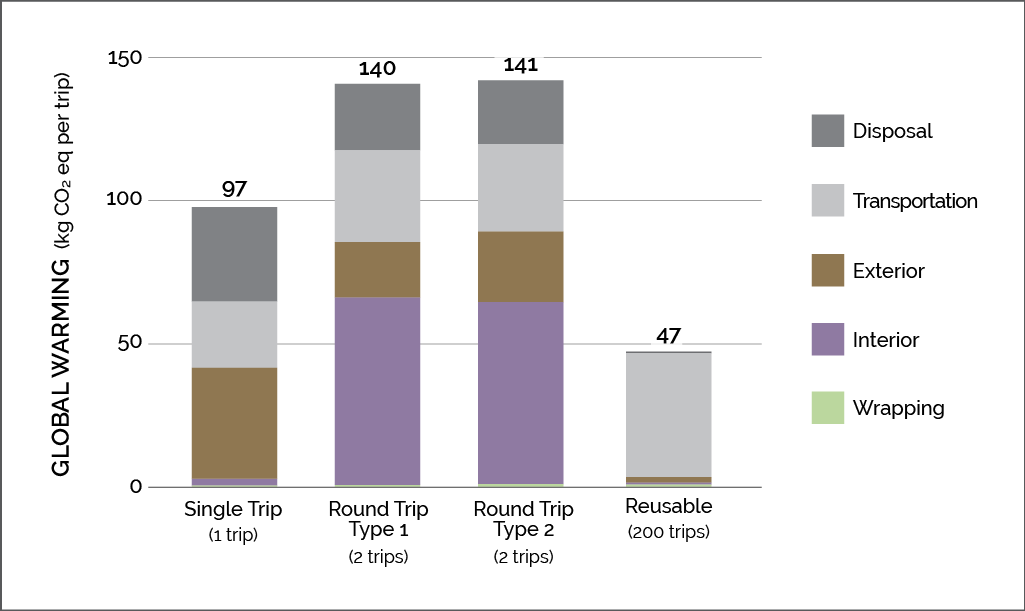

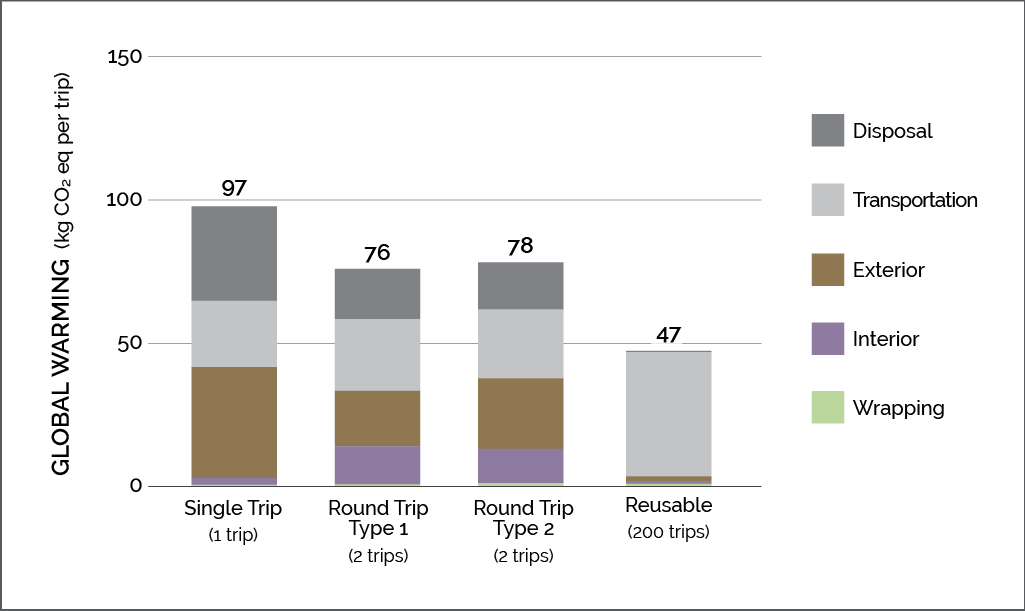

Figures 3a and 3b divide the flatwork crates into five categories (represented by color blocks) according to the contribution of carbon emissions for each life cycle stage or material. For the round trip type 1 and 2 crate designs shown in Figures 2 and 3a, the density for the urethane and esterfoam was assumed to be 7.8 pounds per cubic foot (pcf) (‘set 1’), while for Figure 3b, these foam densities were assumed to be 1.55 pcf (‘set 2’). The same volume of foam was used in each scenario; the flat crate round trip type 1 used 7.17 cubic feet and the flat crate round trip type 2 used 7.05 cubic feet. Comparison of Figures 3a and b shows how the results change for the round trip crates if lower density foams were used.

For the single trip crate in set 1 (Figure 3a), the impacts from the exterior materials and the crate disposal dominate. Because these single trip crates use interior Ethafoam strips instead of foam panels and lighter LDPE film instead of Tyvek, the contribution of interior and wrapping materials is minimal. In contrast, for the round trip crates, the interior materials dominate, driven by the extensive use of petrochemical-based foams. The reusable crates also rely on interior foams, but because their life cycle use is spread out over 200 trips instead of 2 trips for the round trip crates, the contribution of foams is much smaller. Because the wrapping materials are not reused in any scenario, their contribution is constant (and modest) among the round trip and reusable designs.

For the single trip crate in set 2 (Figure 3b), the impacts from the exterior materials and the crate disposal still dominate. Because these single trip crates use interior Ethafoam strips instead of foam panels and lighter LDPE film instead of Tyvek, the contribution of interior and wrapping materials is minimal. For the round trip crates, the reduced density of the foams significantly lowers the impact of the interior. Both are now dominated by the impacts resulting from transportation and exterior materials, particularly the plywood. The reusable crates remain dominated by transportation. Although the reusable crate has the lowest total impact per trip, the round trip crates are now significantly closer in impact than in set 1.

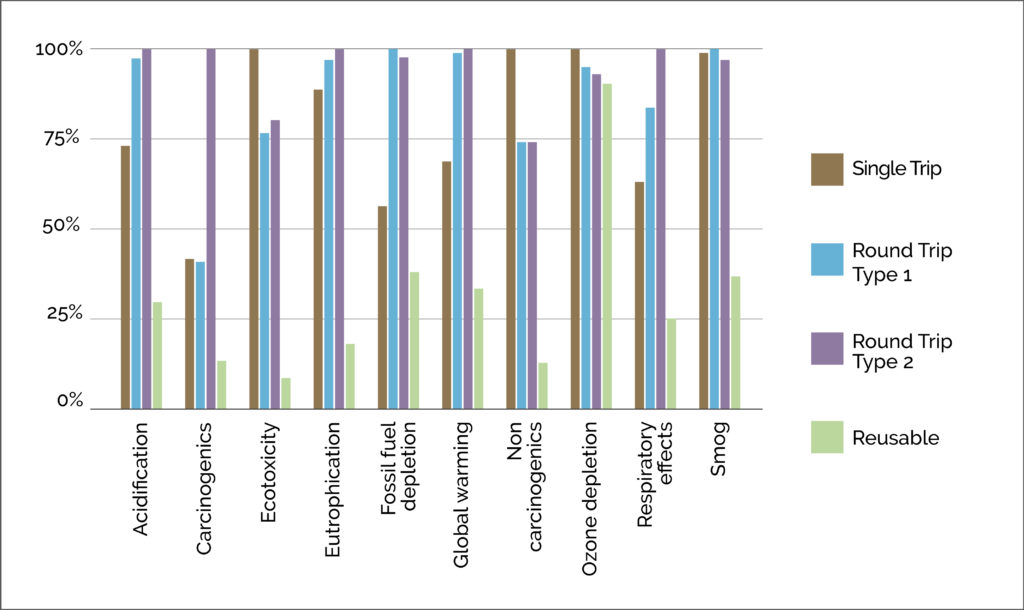

Global warming is just one environmental impact category. Figure 4 illustrates the case study results for set 1 flatwork crates across a suite of impact categories, shown as a percentage of the maximum result in each category. Per trip, the reusable crate resulted in the lowest impact across all categories. This consistent result means that the reusable crate is without major environmental trade-offs and can be considered the environmentally preferable option. The round trip type 2 crate resulted in the highest environmental impact across five of the ten categories including global warming, while the single trip crate resulted in the highest impact in ecotoxicity and non-carcinogenics driven by municipal solid waste incineration.

Summary

Transportation of cultural heritage objects involves high impact materials and actions, and depends on established products and designs to keep objects safe. The information provided through this LCA enables cultural heritage professionals to progress towards more sustainable practices while working within established parameters by choosing reusable crates and reducing foam amounts. The reusable crates result in lower impacts across a range of environmental considerations. Foams, regardless of their type, can be a major source of environmental impacts, underscoring the potential benefits of replacement with lower impact materials or new low-carbon foams and polymers. Using lower density foam drastically reduced the impacts as seen in Figures 3a and 3b. Hopefully these findings will encourage more research and further exploration of new sustainable materials that perform equally as well as the items they replace. Other actions to reduce impacts while still choosing high impact materials could include reusing crate materials through disassembly to reduce the impact of each material,18 or designing crates for varied uses, such as a crate that becomes the base of a display case for the object it transports. Transportation resulted in high impacts throughout as well. Lowering the weight of the crate, possibly by using lighter materials for the crate shell, would reduce these outcomes.

The study considered four types of crates and two sizes that broadly represent typical construction, but results differ depending on variables such as crate size, materials, foam density, object weight, and distance traveled. This work is a follow-up to an earlier 2016 LCA study that examined the influence of couriers and transportation options with just a single crate design; those results should be referenced for in depth environmental impacts when decision-making around loans.19

A final, critical point is that the environmental results from LCA are just one consideration for sustainability in cultural heritage. The safety of objects, the safety of staff, practical cost considerations, and especially the cultural value of viewing cultural heritage in person are all vital as well. The best options are those that can simultaneously reduce costs and environmental impacts, while preserving cultural heritage for the enrichment of future generations.

PROJECT TEAM

Authors: Sarah Sanchez, Sarah Nunberg

Collaborators: Sarah Sutton, Matthew Eckelman, Meg Colbert, Al Carver-Kubik

LCA Modeling Students: Aidan Travers, Corey Kershaw, Emily Eastman, Krissy Govertsen, Sarah Hossain, and Ying Wang

Figures and illustrations: Varnika Kundu, Hyunah Oh, Eric O’Toole

PROJECT HISTORY

Organized efforts to introduce LCA to U.S. cultural heritage preservation professionals began in 2012 with a series of six LCA case studies conducted as a collaboration between conservators and environmental engineers, in partnership with the MFA Boston. FAIC was awarded a Tier I grant in 2016 and a Tier II grant in 2020 from the National Endowment for the Humanities to expand the case study research and develop a carbon calculator for individual materials under the project Sustainability Tools in Culture Heritage, STiCH,20 available to visitors to the AIC website.21

18 Paul Speh, chief packer at The Brooklyn Museum successfully deconstructs and reuses packing material for custom made crates (personal communication).

19 Nunberg, Sarah, Matthew J. Eckelman, and Pamela Hatchfield. 2016. “Life Cycle Assessments of Loans and Exhibitions: Three Case Studies at the Museum Fine Arts, Boston.” Journal of the American Institute for Conservation 55 (1): 2-11. https://doi.org/10.1080/01971360.2015.1112465.

20 Foundation for Advancement in Conservation (FAIC). 2021. “Sustainability Tools in Cultural Heritage (STiCH).” https://stich.culturalheritage.org/.

21 American Institute for Conservation (AIC). 2021. Cultural Heritage. https://www.culturalheritage.org/.

References

articheck. n.d. “Introducing…Virtual Courier: The world’s first software system designed to reduce risk before, during, and after shipment.” https://www.articheck.com/virtual-courier/.

Barber, Chris. 2015. “Dynamic Cushion Curve Prediction – An Improved Formula for Practical Use in Preventative Conservation.” Preparation, Art Handling, Collections Care Information Network (PACCIN). https://www.paccin.org/content.php?293-Dynamic-Cushion-Curve-Prediction .

Canadian Conservation Institute. 2020. “The CCI Chanel Crate: Making a Lightweight, Reusable Crating System – Canadian Conservation Institute (CCI) Notes 20/1.” https://www.canada.ca/en/conservation-institute/services/conservation-preservation-publications/canadian-conservation-institute-notes/lightweight-reusable-crate.html.

Canadian Conservation Institute. 2021. “Five Steps to Safe Shipment – Canadian Conservation Institute (CCI) Notes 20/3.” https://www.canada.ca/en/conservation-institute/services/conservation-preservation-publications/canadian-conservation-institute-notes/five-steps-safe-shipment.html.

Clarke, Roddy. 2019. “UK Startup Launches New Art Packaging Solution Set To Revolutionize The Industry.” Forbes, September 28, 2019. https://www.forbes.com/sites/roddyclarke/2019/09/28/uk-start-up-launches-new-art-packaging-solution-set-to-revolutionise-the-industry/?sh=10e4e5ae6283.

ecoinvent. 2020. “Systems Models in ecoinvent 3: Allocation at the Point of Substitution.” https://www.ecoinvent.org/database/system-models-in-ecoinvent-3/apos-system-model/allocation-at-the-point-of-substitution.html.

Environmental Paper Network. 2021. “Paper Calculator: presented by environmental paper network.” https://c.environmentalpaper.org/.

Fava, James A., and Society of Environmental Toxicology and Chemistry. 1991. A technical framework for life-cycle assessment: workshop report; August 18-23, 1990. N.p.: SETAC.

GreenDelta. 2020. “openLCA.” https://www.openlca.org/.

International Organization for Standardization (Switzerland) Environmental Management. 2006. “Life cycle assessment – Requirements and guidelines.” https://www.iso.org/standard/38498.html.

Nunberg, Sarah, Matthew J. Eckelman, and Pamela Hatchfield. 2016. “Life Cycle Assessments of Loans and Exhibitions: Three Case Studies at the Museum Fine Arts, Boston.” Journal of the American Institute for Conservation 55 (1): 2-11. https://doi.org/10.1080/01971360.2015.1112465.

sphera. 2020. “GaBi Packaging Calculator – Sustainable Packaging Design.” https://gabi.sphera.com/international/software/gabi-envision/gabi-packaging-calculator/.

UK Registrars Group. 2020. Guidance notes: The Virtual Courier (UK and Europe). https://www.ukregistrarsgroup.org/wp-content/uploads/2020/06/UKRG-Virtual-Courier-Guidance.pdf.

UNEP. 2005. Life Cycle Approaches: the Road from Analysis to Practice. N.p.: UNEP/SETAC, Life Cycle Initiative, Paris.

U.S Environmental Protection Agency. 2012. “Tool for Reduction and Assessment of Chemicals and Other Environmental Impacts (TRACI).” https://www.epa.gov/chemical-research/tool-reduction-and-assessment-chemicals-and-other-environmental-impacts-traci.

Vignon, Bruce W., D. Tolle, B. Cornaby, H. Latham, C. Harrison, T. Boguski, R. G. Hunt, and J. Sellers. 2020. Life-cycle assessment: Inventory guidelines and principles. N.p.: CRC Press.

2 replies on “Crates for 3D Objects and Flatwork”

Hi, what kind of wool was used? was this a felted product or washed wool? Thanks!

Hi Megan,

sorry for the late reply. I am not sure I understand your question. Please clarify and I will try and respond faster.

best, Sarah Nunberg