Background

Backing boards are mechanically attached to the auxiliary support on the reverse of a painting serving several purposes, including (but not limited to): protection from physical damage, buffer fluctuations in relative humidity, prevention of dirt and debris from collecting behind the auxiliary support bars, and vibration reduction during travel. Boards used for backing paintings are also used to support objects, build travel and storage boxes, and function as trays or surface padding under an object during treatment and handling. This study focuses on boards as they function to back paintings, but is applicable for many other purposes.

There is no consensus as to the ideal backing board material. Conservators generally select backing boards based on individual experience and preference regarding rigidity, cost, weight, and/or the ambient climate. Instances where material choice is not restricted by standards presents an opportunity for informed sustainable design, and for selecting products with the lowest environmental impact. This life cycle assessment (LCA) outlines the impact of each board and can help guide us through our choices.

This LCA case study compares four backing board materials: archival FoamCore, archival corrugated blue board, Coroplast, and standard corrugated non-archival cardboard. Often these materials function interchangeably, yet cultural heritage professionals tend to automatically design boxes and supports using archival materials even if the object they support does not require the low-reactive environment archival boards provide. The non-archival corrugated board is not optimal for contact with reactive materials, but when choosing between such similarly functioning products, environmental impact can be a deciding factor.

LCA Modeling

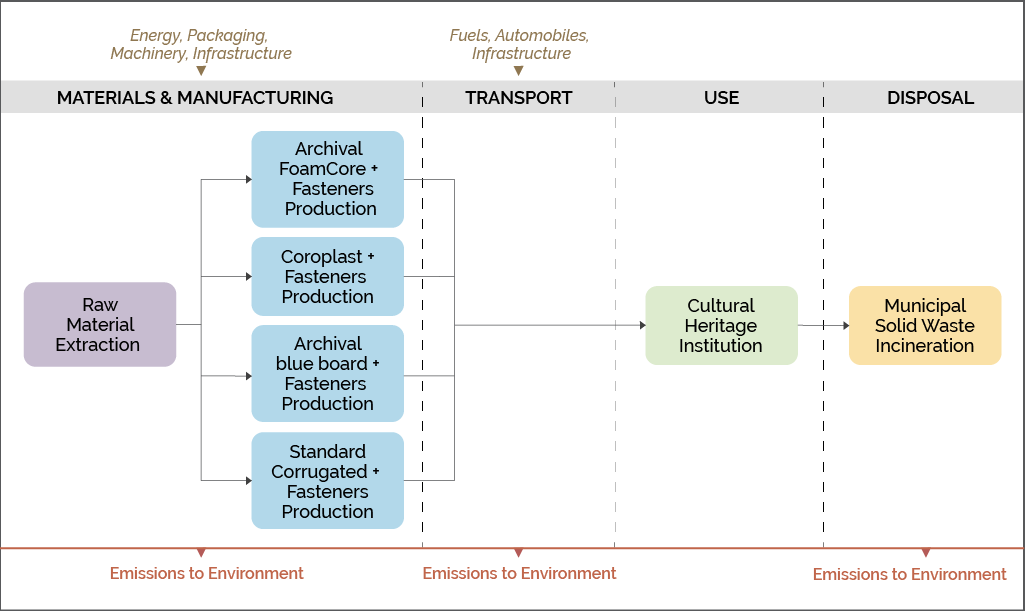

Life cycle assessment is an internationally standardized (ISO 14040) modeling tool used to quantify environmental and health impacts of a product or process.1 LCA takes a holistic, systems approach by considering sustainability over the entire product life cycle, including raw materials extraction, manufacturing, transport, use, and end-of-life.2,3,4 LCA has been used across all types of sectors to inform procurement decisions, and provides the scientific basis for all carbon, water, and environmental footprinting. In some relevant examples, LCA has been used to build popular online calculators that compare different grades of paper or packaging materials.5,6

This case study covers a ‘cradle-to-grave’ scope, examining all stages of the product life cycle (Figure 1). LCA compares products according to the primary function that they fulfill, called the functional unit, which is a quantitative measure. The functional unit for this case study is an area of 2,400 square inches of protection for a painting’s auxiliary support (which translates to a 40 inch x 60 inch standard sheet). Modeling was completed using the free, open source software OpenLCA (v1.10.3)7 with material-specific data from the ecoinvent database (v3.7, APOS).8 The environmental and human health impacts from each product life cycle were calculated using the Tool for the Reduction and Assessment of Chemical and other environmental Impacts (TRACI) (v2.1)9 impact assessment method developed by the U.S. Environmental Protection Agency. Further information can be found in the STiCH Information Sheet: Life Cycle Assessement Explained.10

1 International Organization for Standardization (Switzerland) Environmental Management. 2006. “Life cycle assessment – Requirements and guidelines.” https://www.iso.org/standard/38498.html.

2 Vigon, Bruce W., D. Tolle, B. Cornaby, H. Latham, C. Harrison, T. Boguski, R. G. Hunt, and J. Sellers. 2020. Life-cycle assessment: Inventory guidelines and principles. N.p.: CRC Press.

3 Fava, James A., and Society of Environmental Toxicology and Chemistry. 1991. A technical framework for life-cycle assessment: workshop report; August 18-23, 1990. N.p.: SETAC.

4 UNEP. 2005. Life Cycle Approaches: the Road from Analysis to Practice. N.p.: UNEP/SETAC, Life Cycle Initiative, Paris.

5 Environmental Paper Network. 2021. “Paper Calculator: presented by environmental paper network.” https://c.environmentalpaper.org/.

6 sphera. 2020. “GaBi Packaging Calculator – Sustainable Packaging Design.” https://gabi.sphera.com/international/software/gabi-envision/gabi-packaging-calculator/.

7 GreenDelta. 2020. “openLCA.” https://www.openlca.org/.

8 ecoinvent. 2020. “System Models in ecoinvent 3: Allocation at the Point of Substitution.” https://www.ecoinvent.org/database/system-models-in-ecoinvent-3/apos-system-model/allocation-at-the-point-of-substitution.html.

9 U.S Environmental Protection Agency. 2012. “Tool for Reduction and Assessment of Chemicals and Other Environmental Impacts (TRACI).”

https://www.epa.gov/chemical-research/tool-reduction-and-assessment-chemicals-and-other-environmental-impacts-traci.

10 Foundation for Advancement in Conservation (FAIC). 2021. “Sustainability Tools in Cultural Heritage (STiCH).” https://stich.culturalheritage.org/.

Methods

The four backing boards range in thickness from 1/8 – 3/16 inches and in weight from 1.5 to 2.5 pounds. Archival FoamCore is made of polystyrene (PS) foam between archival buffered paper (without adhesive between layers). Coroplast was modeled as extruded polypropylene (PP). Archival corrugated blue board (2 ply) is made of virgin board buffered with 3% calcium carbonate, by weight. The corrugated layers are adhered with maize starch and potato starch. The standard corrugated board is a mix of virgin and recycled content containerboard also adhered with maize and potato starch glue. The boards are attached to the painting auxiliary support with 10 flat wood zinc-plated steel screws and 10 countersunk stainless steel washers. Packaging (for the boards) was modeled as low density polyethylene (LDPE) packaging film and standard corrugated board. Packaging (for the fasteners) was modeled as standard corrugated board. Product composition, weight, and other specifications were collected from popular online retailers. Information about how these products are typically selected was obtained through conversations with conservators and art packers. Transportation of the products and their packaging from the factory to the consumer was assumed to be 1000 kilometers by truck (as a default/average distance from the manufacturing sites to the cultural heritage institutions). At the end-of-life stage, archival and standard corrugated boards were assumed to be recycled, while the archival FoamCore and LDPE packaging films were disposed of as municipal solid waste. Because recycling polypropylene (Coroplast) varies state to state, it was also modeled as solid waste.

Excluded from this study are the inputs and materials needed to produce the paintings, any additional materials or protective equipment used to install the backing boards (e.g, gloves, screwdriver), and energy used during the storage or display of the painting throughout the lifetime of the backing board. 11

11 National Geographic and Sea Studios Foundation. n.d. “Smart Plastics Guide.” National Geographic’s Strange Days on Planet Earth. https://www-tc.pbs.org/strangedays/pdf/StrangeDaysSmartPlasticsGuide.pdf.

Results

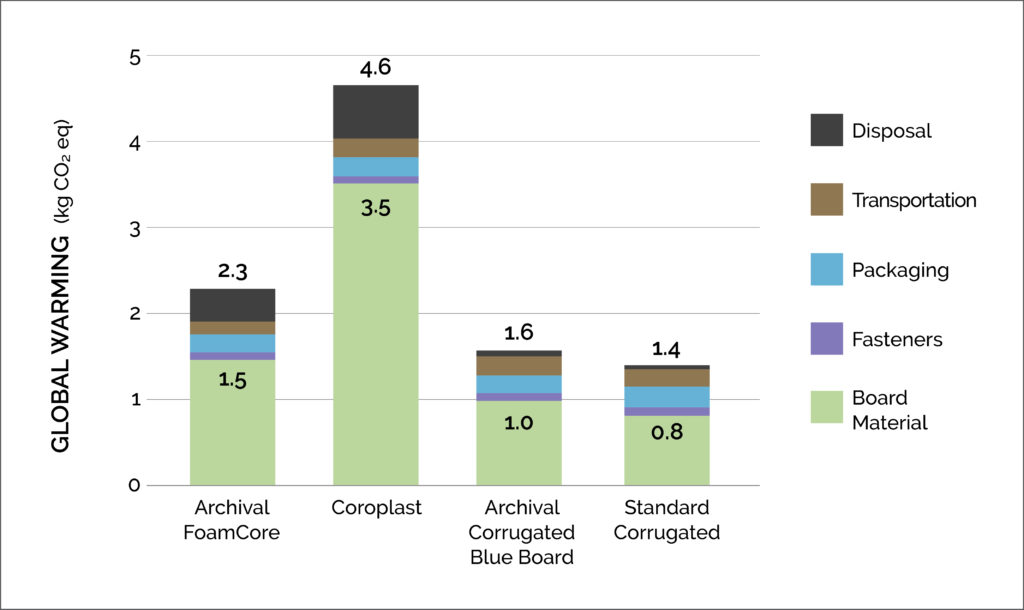

The backing board results in Figure 2 compare the global warming impact of the four board assembly options. The boards were modeled assuming an equal lifetime for each material. The assembly variations are split up into five categories (represented by color blocks) according to the contribution of each phase or material (screws and washers have been added together under the category ‘fasteners’).

The results show that Coroplast has the highest total global warming impact (carbon footprint) at 4.6 kg CO2 eq. Two-thirds (3.5 kg CO2 eq) of its impact is from the production of the board material polypropylene (PP). Polypropylene is known for durability, so extending the lifetime of the Coroplast (compared to the other three boards) or reusing it multiple times, would reduce its relative impact. FoamCore has the second highest impact, again dominated by material production, split between polystyrene (PS) foam (1.0 kg CO2 eq) and the archival paper (0.5 kg CO2 eq).

The standard corrugated board has the lowest impact of the four boards studied, with a 20% lower impact than the archival blue board. One might have expected a greater impact difference between the virgin archival board and the non-archival corrugated board. Although recycling reduces the use of virgin material, it requires energy and resources for hauling to collect paper, and hydropulping/de-inking to obtain usable pulp from recycled paper. The virgin pulp and 3% calcium carbonate buffer contribute to the higher impact of the archival blue board.

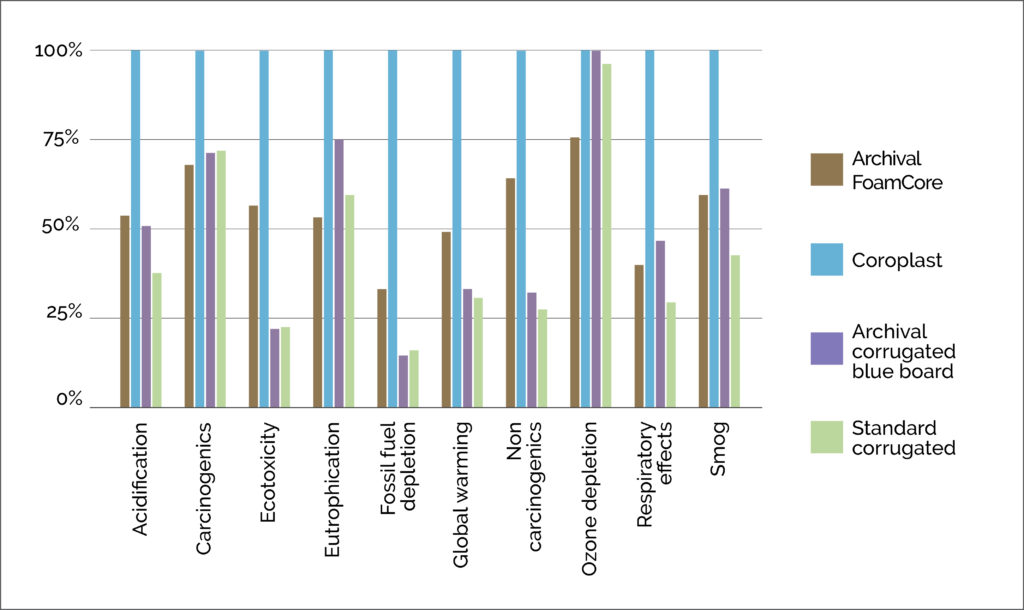

Global warming is just one environmental impact category. There are many others that can influence sustainable choices. Figure 3 illustrates the case study results for a suite of impact categories, shown as a percentage of the maximum result in each category. The results show that Coroplast has the highest environmental impacts across nearly all categories. The archival and standard corrugated have less than half of the impacts compared to Coroplast for most categories, but the Coroplast, archival and standard corrugated have similar results for ozone depletion.

The areas where the archival blue board and the corrugated board show the greatest differences are acidification, eutrophication, respiratory effects, and smog (see STiCH Information Sheet: Life Cycle Assessment Explained for definitions of impact categories). In each of these cases the corrugated board from mixed content without the calcium carbonate buffer shows 10-20% less impact than the virgin buffered archival blue board.

Summary

LCA was useful in identifying the material production processes that drive the impacts of the four board types. By identifying these impacts, the LCA demonstrates that Coroplast has a higher impact compared to the other three materials studied, and indicates that Coroplast should be used selectively and reused as much as possible before final disposal, as recommended by the U.S. EPA’s waste management hierarchy.12

The study also shows that corrugated cardboard with recycled content has a discernibly lower impact than archival blue board, again demonstrating the importance of selective material use. Although the differences between the boards with virgin and recycled content are not as drastic as the comparison with the Coroplast, when given the option, using either corrugated board will result in lower impact overall. For materials so ubiquitous in cultural heritage preservation, understanding these assumptions and realities is key to informed decision-making. Not all cultural heritage requires archival packing material and this study supports selecting it only when necessary for more sustainable practices.

PROJECT TEAM

Authors: Melissa Amundsen, Sarah Sanchez, Sarah Nunberg

Collaborators: Sarah Sutton, Matthew Eckelman, Al Carver-Kubik

Figures and illustrations: Varnika Kundu, Hyunah Oh, Eric O’Toole

PROJECT HISTORY

Organized efforts to introduce LCA to U.S. cultural heritage preservation professionals began in 2012 with a series of six LCA case studies conducted as a collaboration between conservators and environmental engineers, in partnership with the MFA Boston. FAIC was awarded a Tier I grant in 2016 and a Tier II grant in 2020 from the National Endowment for the Humanities to expand the case study research and develop a carbon calculator for individual materials under the project Sustainability Tools in Culture Heritage, STiCH,13 available to visitors to the AIC website.14

12 U.S Environmental Protection Agency. 2017. “Non-Hazardous Materials and Waste Management Hierarchy.” Sustainable Materials Management. https://www.epa.gov/smm/sustainable-materials-management-non-hazardous-materials-and-waste-management-hierarchy.

13 Foundation for Advancement in Conservation (FAIC). 2021. “Sustainability Tools in Cultural Heritage (STiCH).” https://stich.culturalheritage.org/.

14 American Institute for Conservation (AIC). 2021. Cultural Heritage. https://www.culturalheritage.org/.

Material Sources

ARTCARE FOAMCORE BOARD (Polystyrene, archival paper) Talas 330 Morgan Ave Brooklyn, NY 11211; 212-219-0770 https://www.talasonline.com/Artcare-FoamCore-Board

COROPLAST (polypropylene) Talas 330 Morgan Ave Brooklyn, NY 11211; 212-219-0770 https://www.talasonline.com/Coroplast

COUNTERSUNK WASHER (stainless steel) Grainger Brooklyn Branch 815 3rd Ave Brooklyn, NY 11232 https://www.grainger.com/product/FABORY-Washer-1NU85

FLAT WOOD SCREW (zinc plated steel) Grainger Brooklyn Branch 815 3rd Ave Brooklyn, NY 11232 https://www.grainger.com/product/FABORY-Wood-Screw-1KU68

HERITAGE® ARCHIVAL CORRUGATED BLUE BOARD (100% alpha cellulose, 3% calcium carbonate buffer, starch adhesive) Talas 330 Morgan Ave Brooklyn, NY 11211; 212-219-0770 https://www.talasonline.com/Heritage-Corrugated

STANDARD CORRUGATED CARDBOARD (virgin and recycled container board, starch adhesive) Box For Less Headquarters 12427 Sylmar, CA 91342 https://www.boxforless.com/40×60-200-single-wall-corrugated-sheets

References

ecoinvent. 2020. “System Models in ecoinvent 3: Allocation at the Point of Substitution.” https://www.ecoinvent.org/database/system-models-in-ecoinvent-3/apos-system-model/allocation-at-the-point-of-substitution.html.

Environmental Paper Network. 2021. “Paper Calculator: presented by environmental paper network.” https://c.environmentalpaper.org/.

Fava, James A., and Society of Environmental Toxicology and Chemistry. 1991. A technical framework for life-cycle assessment: workshop report; August 18-23, 1990. N.p.: SETAC.

GreenDelta. 2020. “openLCA.” https://www.openlca.org/.

International Organization for Standardization (Switzerland) Environmental Management. 2006. “Life cycle assessment – Requirements and guidelines.” https://www.iso.org/standard/38498.html.

National Geographic and Sea Studios Foundation. n.d. “Smart Plastics Guide.” National Geographic’s Strange Days on Planet Earth. https://www-tc.pbs.org/strangedays/pdf/StrangeDaysSmartPlasticsGuide.pdf.

sphera. 2020. “GaBi Packaging Calculator – Sustainable Packaging Design.” https://gabi.sphera.com/international/software/gabi-envision/gabi-packaging-calculator/.

UNEP. 2005. Life Cycle Approaches: the Road from Analysis to Practice. N.p.: UNEP/SETAC, Life Cycle Initiative, Paris.

U.S Environmental Protection Agency. 2012. “Tool for Reduction and Assessment of Chemicals and Other Environmental Impacts (TRACI).” https://www.epa.gov/chemical-research/tool-reduction-and-assessment-chemicals-and-other-environmental-impacts-traci.

U.S Environmental Protection Agency. 2017. “Non-Hazardous Materials and Waste Management Hierarchy.” Sustainable Materials Management. https://www.epa.gov/smm/sustainable-materials-management-non-hazardous-materials-and-waste-management-hierarchy.

Vigon, Bruce W., D. Tolle, B. Cornaby, H. Latham, C. Harrison, T. Boguski, R. G. Hunt, and J. Sellers. 2020. Life-cycle assessment: Inventory guidelines and principles. N.p.: CRC Press.